Triple-Phase Power: What’s the Big Deal?

So, you’ve probably heard the term ‘triple-phase electric power’ thrown around, especially if you’re dealing with anything more serious than your average toaster. It sounds complicated, right? Well, it doesn’t have to be. Think of it like this: single-phase power is like a single-cylinder engine, chugging along with its ups and downs. Triple-phase, on the other hand, is more like a smooth, multi-cylinder engine that just keeps going. This article breaks down why triple-phase electric power is such a big deal, especially for businesses and heavy-duty stuff.

Key Takeaways

- Triple-phase electric power uses three separate currents, each offset by 120 degrees, which means power delivery is much more consistent than single-phase.

- It can move more power using less wiring compared to single-phase systems, making it more efficient.

- This efficiency and higher power capacity make it ideal for heavy machinery, data centers, and large buildings.

- Triple-phase power is generated by spinning a magnet past three wires, creating alternating currents that are out of sync.

- While single-phase is common in homes, triple-phase is the standard for industrial and commercial applications where high power demands are the norm.

Understanding Tripple-Phase Electric Power Basics

So, what’s the big deal with triple-phase power? It sounds complicated, but it’s really just a smarter way to send electricity around. Think of it like this: instead of just one push of power, you get three, timed just right.

What Constitutes Tripple-Phase Power

Triple-phase power, or three-phase as it’s more commonly called, uses three separate alternating current (AC) power lines. Each of these lines carries an AC current that’s out of sync with the others. This isn’t some random jumble; it’s a carefully orchestrated system. We’re talking about how three-phase power works, and it all comes down to timing and separation.

The 120-Degree Phase Separation Explained

This is where the magic happens. In a three-phase system, the three AC currents are separated by 120 degrees. Imagine three waves, each starting its cycle a little after the last one. When one wave is at its highest point, the other two are somewhere else in their cycle. This 120-degree separation is key to how alternating current power explained in a more efficient way.

- Phase 1: Peaks at a certain time.

- Phase 2: Peaks 120 degrees after Phase 1.

- Phase 3: Peaks another 120 degrees after Phase 2 (or 240 degrees after Phase 1).

This staggered timing means that power is always being supplied. Unlike single-phase power, which has moments where the power dips, three-phase keeps a more consistent flow. It’s like having three people pedaling a bicycle, each taking a turn pushing down, rather than just one person doing all the work.

Continuous Power Delivery Unlike Single-Phase

Because of that 120-degree separation, the total power delivered by a three-phase system remains remarkably constant. There are no big dips or valleys in power output. This steady stream is a huge advantage for equipment that needs a reliable power source, like large motors or sensitive electronics. It’s a much smoother ride for the electricity.

This consistent power delivery is a major reason why three-phase is used for industrial applications. It means machinery can run more smoothly and efficiently, without the power fluctuations that could cause problems in single-phase systems.

Think of it like a three-cylinder engine versus a single-cylinder engine. The three-cylinder engine fires more often, giving you a smoother, more consistent power output. That’s exactly what three-phase power does for electrical loads.

The Advantages of Tripple-Phase Electric Power

So, why all the fuss about three-phase power? Well, it turns out there are some pretty solid reasons why it’s the go-to for so many industrial electricity supply needs. It’s not just a little bit better; it’s a whole different ballgame compared to the single-phase power most of us have at home.

Delivering More Power With Less Wiring

One of the biggest wins for three-phase systems is efficiency in terms of materials. You can actually transmit more power using less copper wire compared to a single-phase system with the same voltage. Think about it: instead of needing two wires to carry the current, you’re using three (or sometimes four, if a neutral wire is included). This setup allows for a more balanced load, and the currents in the wires tend to cancel each other out, meaning the neutral wire carries very little current, or none at all in a perfectly balanced system. This reduction in the need for heavy-duty neutral wiring saves on material costs and makes installation simpler, especially for high-density power demands.

Efficiency Gains Through Power Delivery

This is where the magic of the 120-degree phase separation really shines. Unlike single-phase power, which has peaks and valleys in its power delivery, three-phase power provides a much more constant and steady flow of energy. Imagine comparing a single-cylinder engine to a three-cylinder engine; the three-cylinder runs much smoother. This constant power means that motors and other equipment don’t have to deal with the fluctuations. They can operate more smoothly, use less energy overall, and last longer because they aren’t constantly being jolted by power variations. It’s a key reason why three-phase is so popular in industrial settings.

Supporting High-Density Power Demands

As technology advances, the power requirements for equipment, especially in places like data centers, keep going up. Trying to meet these high demands with single-phase power would require incredibly thick, expensive, and difficult-to-manage wiring. Three-phase power, however, is built for this. It can handle much larger loads without needing proportionally larger wires. This makes it the practical and economical choice for powering large banks of servers, heavy manufacturing machinery, and large commercial buildings. It’s one of the core advantages of polyphase systems that keeps modern industry running.

The consistent power output of three-phase systems is a major factor in the efficiency and longevity of electrical equipment, particularly motors. This steady energy flow reduces mechanical stress and heat generation, leading to better performance and fewer breakdowns over time.

Comparing Tripple-Phase to Single-Phase Power

So, you’ve heard about three-phase power, but how does it stack up against the single-phase power most homes use? It’s not just about having more wires; it’s a different way of getting electricity to where it needs to go.

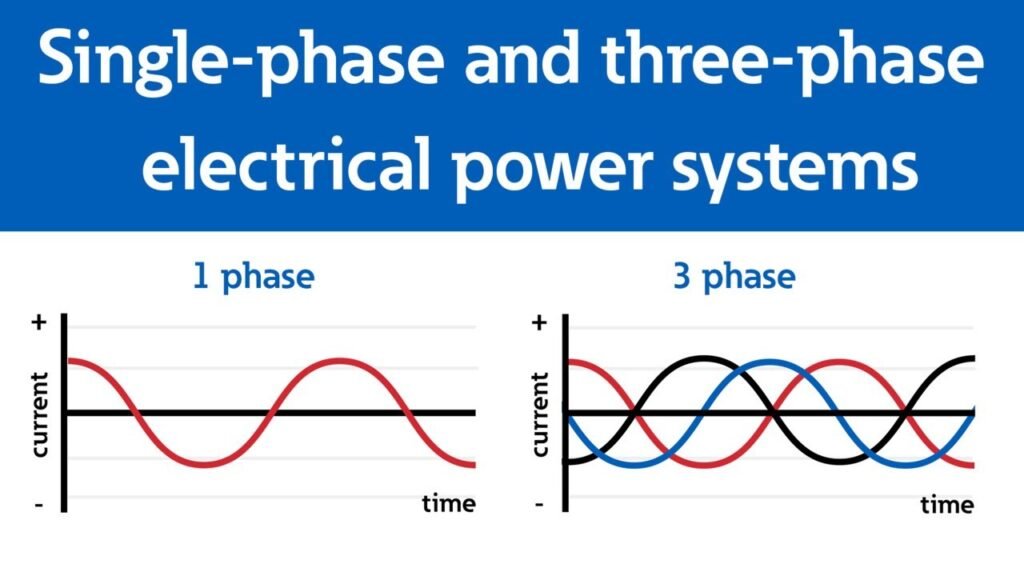

Fundamental Differences in Power Delivery

Single-phase power is what you’re likely familiar with. It uses two wires – a hot wire and a neutral wire – to send electricity. Think of it like a single wave of power. This wave goes up and down, and at two points in each cycle, the power actually drops to zero. For running lights or a toaster, this brief dip isn’t a big deal. But for things like big motors or sensitive electronics, it can cause issues.

Three-phase power, on the other hand, uses three separate currents, each offset by 120 degrees. Imagine three waves, staggered so that when one wave is dipping, another is rising. This means that power is always being supplied, never dropping to zero. It’s like having three people pushing a merry-go-round at different times instead of just one – much smoother and more consistent.

This constant flow of power is a big reason why three-phase is preferred for heavy-duty applications. It means equipment can run more steadily and efficiently, without the little power interruptions inherent in single-phase.

Voltage and Current Considerations

When we talk about power, we often think in terms of kilowatts (kW). But in electrical systems, you’ll also hear about kilovolt-amperes (kVA). KVA is the total power supplied, while kW is the useful power that actually does work. The difference is the power factor (PF), which tells you how efficiently the system is using power. The formula is simple: kW = kVA × PF. For instance, a 10 kVA system with a 0.8 power factor provides 8 kW of useful power. Many industrial loads naturally have a power factor around 0.8, meaning there’s always some ‘invisible’ power, called reactive power, that doesn’t do work but is still part of the electrical flow. Understanding this is key to correctly sizing equipment, like generators, to avoid problems [b90c].

Here’s a quick look at how power output differs:

| System | Voltage (example) | Current (per phase) | Power Formula (simplified) | Power Output (example) |

|---|---|---|---|---|

| Single-Phase | 120V | 20A | V × I | 2400 Watts |

| Three-Phase | 120V | 20A (per phase) | V × I × √3 | 4157 Watts |

As you can see, even with the same voltage and current per wire, a three-phase system can provide significantly more power. This is because the three phases work together, and the math involves the square root of three (approximately 1.732).

Applications Differentiating the Two

So, where do you typically find each type of power?

- Single-Phase: This is the standard for most homes and small businesses. It’s perfectly fine for lighting, heating, standard appliances, and smaller motors. Think of your typical household outlets and the power they provide.

- Three-Phase: You’ll find this in industrial settings, large commercial buildings, and places with heavy machinery or high-density power needs, like data centers. It’s ideal for large electric motors, industrial equipment, and anything that needs a consistent, high level of power.

Essentially, if your power needs are relatively low and consistent, single-phase is usually sufficient. But when you start dealing with larger loads, motors, or the need for more efficient power transmission, three-phase becomes the clear choice.

Practical Applications of Tripple-Phase Power

So, where do we actually see this three-phase power stuff being used? It’s not just some abstract concept for engineers; it’s the workhorse behind a lot of the big stuff we rely on.

Powering Heavy Machinery and Industrial Equipment

Think about factories, manufacturing plants, or even large construction sites. You’ve got big motors running assembly lines, massive pumps moving fluids, and heavy-duty presses shaping metal. These kinds of machines need a lot of consistent power to operate smoothly and efficiently. Single-phase power just wouldn’t cut it. It would be like trying to power a bulldozer with a lawnmower engine – it just doesn’t have the grunt.

- Industrial Motors: Three-phase power is ideal for running electric motors because it provides a constant, rotating magnetic field. This makes the motors simpler, more robust, and more efficient than their single-phase counterparts.

- Manufacturing Equipment: Think lathes, drills, conveyor belts, and robotic arms. All of these often rely on the steady power output of a three-phase system.

- Heavy-Duty Pumps and Compressors: Large-scale fluid movement and air compression systems in industrial settings require the sustained power that three-phase can provide.

The steady, non-fluctuating power delivery of three-phase systems means that machinery can operate at optimal performance without the strain that comes from power dips. This translates to less wear and tear, longer equipment life, and fewer unexpected shutdowns.

Meeting the Demands of Data Centers

Data centers are basically giant buildings filled with computers that are always on. These servers, cooling systems, and networking gear consume a massive amount of electricity, and they need it to be reliable.

- High Power Density: Modern data centers pack a lot of computing power into relatively small spaces. Three-phase power allows them to supply the high wattage needed for these dense racks of equipment without needing excessively thick, expensive wiring.

- Efficiency: Running thousands of servers means a huge electricity bill. The inherent efficiency of three-phase power helps to reduce overall energy consumption.

- Redundancy: While not strictly a three-phase benefit, the ability to easily derive different voltage levels from a three-phase supply aids in creating the complex, redundant power systems that data centers require to stay online.

Efficiency in Commercial and Industrial Buildings

Beyond just the heavy machinery, many larger commercial and industrial buildings use three-phase power for their general electrical needs. This includes things like:

- HVAC Systems: Large air conditioning units and heating systems often use three-phase motors.

- Elevators and Escalators: The motors that move these systems are typically powered by three-phase electricity.

- General Lighting and Outlets: While smaller loads might be split off to single-phase circuits, the main distribution within larger buildings often utilizes three-phase.

Using three-phase power in these settings means that the building’s electrical infrastructure can handle larger loads more efficiently, often with less copper wire compared to a single-phase system designed for the same total power. It’s a more economical and practical way to power larger structures.

The Engineering Behind Tripple-Phase Systems

So, how do we actually make this three-phase power thing work? It’s not magic, though sometimes it feels like it when you see how much power these systems can handle. It all comes down to how the electricity is generated and then managed through transformers and different wiring setups.

How Tripple-Phase Power is Generated

Generating three-phase power starts with a special kind of generator. Instead of just one coil of wire spinning in a magnetic field, these generators have three separate coils. These coils are positioned so that as the generator spins, each coil produces an electrical current that peaks at a different time. Think of it like three people pedaling a bicycle, but each person starts their pedal stroke a little bit after the person before them. This 120-degree separation between the electrical waves is key. It means that power is being supplied pretty much all the time, unlike single-phase power which has noticeable dips.

- Three distinct coils are used in the generator.

- These coils are physically offset from each other.

- The rotation of the generator creates three separate AC waveforms.

- Each waveform is 120 degrees out of phase with the others.

This continuous power delivery is a big reason why three-phase is so good for motors and heavy equipment. It provides a smoother, more consistent force, which is easier on the machinery and often uses less energy overall.

The Role of Transformers in Tripple-Phase

Transformers are super important for three-phase power, just like they are for single-phase. They step voltage up for long-distance transmission and then step it back down for use. In a three-phase system, you’ll often see special three-phase transformers. These are essentially three single-phase transformers combined into one unit, or sometimes built as a single core with three sets of windings. They handle the three separate currents and voltages, making sure they stay properly phased. This allows utilities to efficiently move large amounts of power across the country and then deliver it safely to homes and businesses.

Wiring Configurations: Delta and Wye

When it comes to connecting everything up, there are two main ways three-phase power is wired: Delta and Wye (sometimes called Star). Each has its own advantages.

- Delta (Δ) Connection: In a Delta setup, the three coils are connected end-to-end, forming a triangle. There’s no neutral wire in a pure Delta system. This configuration is often used for higher voltage applications and can be good for motors.

- Wye (Y) Connection: A Wye connection has one end of each coil connected together at a central point, called the neutral point. The other ends of the coils are where the power comes out. This setup provides a neutral wire, which is really useful because it allows you to get both the full three-phase power and single-phase power from the same system. You can tap off between any two of the three main wires, or between one main wire and the neutral.

| Configuration | Common Use Cases | Neutral Wire | Voltage Characteristics |

|---|---|---|---|

| Delta (Δ) | Motors, High Voltage | No | Line voltage is √3 times phase voltage |

| Wye (Y) | Distribution, Mixed Loads | Yes | Line voltage is √3 times phase voltage; provides single-phase option |

Most of the time, the system is designed to be balanced, meaning each phase carries roughly the same amount of power. This keeps things running smoothly and efficiently.

Alternatives and Historical Context

While three-phase power is the standard for a lot of modern electrical needs, it wasn’t always the go-to. Before three-phase really took off, other systems were in play, and some still pop up for specific jobs. It’s interesting to see how we got to where we are.

Exploring Split-Phase Electric Power

Split-phase power is something you’ll find in many homes. It’s basically a way to get two different voltages from a single transformer. This system is common in North America for residential use. It allows for both standard 120-volt outlets and higher 240-volt circuits for things like dryers or water heaters, all from the same basic setup. It’s simpler than three-phase but doesn’t offer the same power density.

Understanding Two-Phase Electric Power

Two-phase power is a bit of a historical footnote, but it was important in the early days of AC electricity. It uses two alternating currents that are out of sync by 90 degrees. Think of it like two waves that peak at different times. Early on, this system was used for things like the first generators at Niagara Falls. However, it had some drawbacks, like needing more wires than later systems. It could be connected to three-phase systems using a special transformer, but eventually, three-phase won out due to its efficiency and simpler wiring.

The Evolution to Modern Three-Phase Systems

The move to three-phase power was a big step. It really got going thanks to inventors like Nikola Tesla and Galileo Ferraris, who were working on electric motors. They realized that using three phases, each 120 degrees apart, created a rotating magnetic field that was perfect for motors. This meant more power could be sent with less wire compared to earlier systems. It also allowed for more efficient power transmission over long distances, which was a game-changer for building out electrical grids.

The development of polyphase systems was key to the widespread adoption of electricity for everything from lighting to heavy industry. If you’re looking at generators, understanding the difference between single-phase and three-phase power is pretty important for matching your equipment’s needs.

So, What’s the Takeaway?

Alright, so we’ve looked at how three-phase power works, with its three separate currents all timed just right. It’s pretty neat how this setup means power delivery is way more consistent, unlike the little dips you get with single-phase. This is a big deal for things that need a steady power flow, like big machines or all that computer gear in data centers. Plus, it can move more power using less wire, which saves money and makes things easier to handle. While single-phase is fine for your home, when you’ve got serious power needs, three-phase really steps up. It’s just a smarter, more efficient way to get the job done for larger operations.

Frequently Asked Questions

What exactly is three-phase power?

Think of three-phase power like having three separate electrical currents working together. Each current is like a wave, and these waves are timed perfectly so they don’t all peak at the same time. They are offset by 120 degrees, meaning there’s always power being sent, unlike single-phase power which has brief moments where no power is delivered.

How is three-phase power different from the power in my house?

The power in your house is usually single-phase. It uses two wires to send power, and the electrical wave has moments where it drops to zero. Three-phase power uses three wires (sometimes four) and has three waves that are staggered. This makes it much smoother and more consistent, which is great for big machines and computers.

Why is three-phase power better for big machines and data centers?

Three-phase power can send more power using less or thinner wires compared to single-phase. This means it’s more efficient and cost-effective for places that need a lot of electricity, like factories or buildings full of computers. It also provides a steadier flow of power, which these devices need to run smoothly.

Can three-phase power deliver more power than single-phase?

Yes, it absolutely can! For the same amount of wiring and voltage, three-phase power can deliver significantly more power. Imagine trying to push a merry-go-round: it’s easier and you can get more speed if three people are pushing at different times rather than just one person pushing whenever they can.

How is three-phase power created?

It’s usually made by spinning a magnet near three separate coils of wire. As the magnet spins, it creates an electrical current in each coil. Because the coils are positioned at different angles, the currents they produce are also out of sync, creating the three distinct phases.

Are there different ways to connect three-phase power?

Yes, there are two main ways: Delta and Wye. In a Delta connection, the three wires form a triangle. In a Wye connection, the wires connect to a central point, like the spokes of a wheel. Both have their uses, but Wye connections often include a fourth ‘neutral’ wire for more flexibility.