Enhancing LiFePO4 Performance: The Role of Graphene in Modern Batteries

So, we’re talking about LiFePO4 batteries here, the kind you find in a lot of electric cars and energy storage systems. When it comes to LiFePO4 performance, these batteries are pretty good, but sometimes they struggle—especially in cold weather. The main issue is they don’t conduct electricity all that well on their own. That’s where graphene comes in. Think of it like adding a superhighway for electrons to travel on, making the whole battery work better. This article is going to break down how adding graphene, and specifically certain types of graphene, can really boost LiFePO4 performance, making these batteries more reliable and powerful, even in tough conditions.

Key Takeaways

- Adding graphene to LiFePO4 cathodes makes them conduct electricity much better, which improves how much power they can store and how fast they can charge and discharge.

- The shape and size of graphene matter; large, curved pieces seem to create a more effective network for electrons to move through.

- Graphene helps LiFePO4 batteries work better even when it’s really cold, overcoming some of the material’s natural conductivity limits.

- Using graphene made from industrial sources and in large amounts is important for making these improved batteries affordable and practical for everyday use.

- Adding about 1% graphene to LiFePO4 electrodes seems to be the sweet spot for getting the best performance without adding too much cost or affecting the battery’s structure.

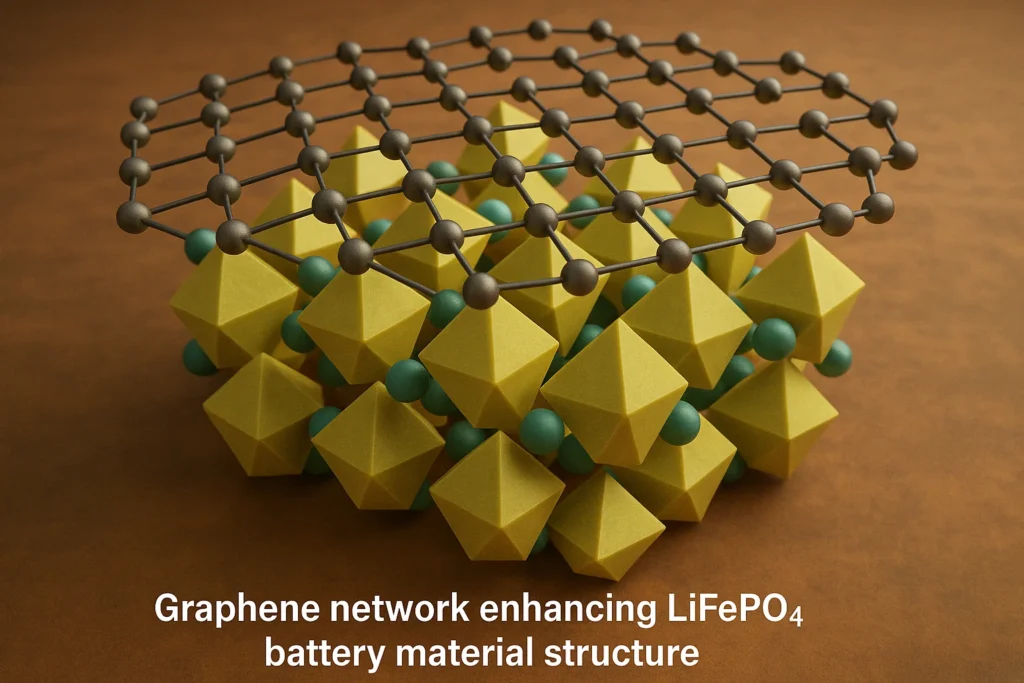

Enhancing LiFePO4 Performance with Graphene

Lithium iron phosphate (LiFePO4 or LFP) is a popular choice for batteries, especially in electric vehicles, because it’s safe and lasts a long time. However, it has some drawbacks, mainly its lower conductivity, which can limit how fast it charges and discharges, and how much energy it can store. This is where graphene comes in. By adding graphene to LFP, we can create graphene enhanced lithium iron phosphate materials that significantly boost battery performance. This approach is key to developing more efficient batteries.

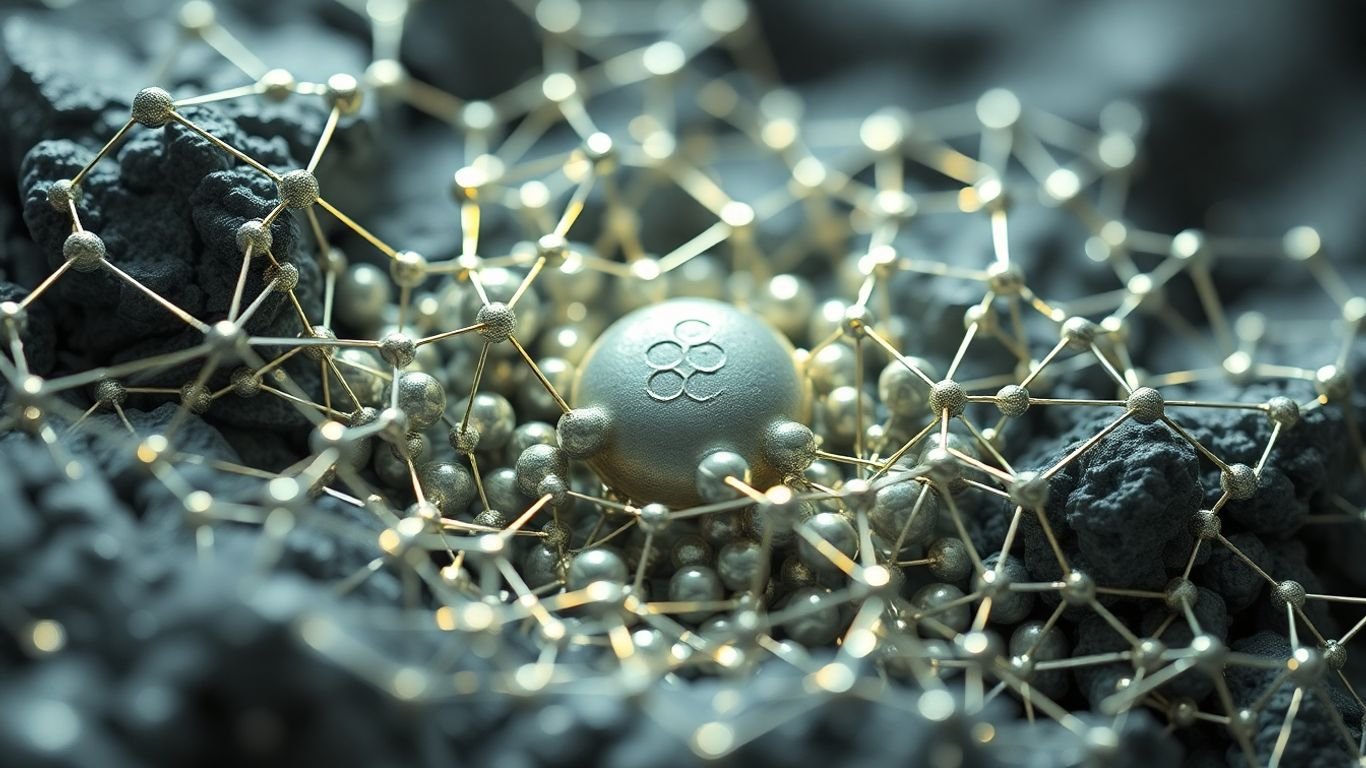

The Role of Graphene in LiFePO4 Performance

One of the main issues with LFP is its natural electrical conductivity. It’s not great, which means electrons have a harder time moving around inside the battery. This sluggish electron movement directly impacts the battery’s ability to deliver power quickly and can reduce its overall capacity. Graphene, with its incredibly high electrical conductivity, acts like a superhighway for electrons. When you mix graphene with LFP particles, you create a conductive network throughout the cathode material. This network makes it much easier for electrons to travel, leading to improved improving LiFePO4 battery efficiency.

Graphene’s Impact on Capacity and Rate Performance

Adding graphene doesn’t just make electrons move faster; it also helps increase the battery’s capacity and its rate performance. Think of it like this: when electrons can move freely, more of the active material (LFP) can be used effectively during charging and discharging. This means you can store more energy and draw more power when needed. Studies have shown that LFP combined with graphene can achieve higher capacities compared to LFP alone. This is particularly noticeable at higher charge and discharge rates, where the graphene network helps maintain performance. The goal is to get the most out of these advanced cathode materials for LiFePO4.

Optimizing Graphene Content for LiFePO4 Composites

While adding graphene is beneficial, it’s not a simple case of ‘more is better.’ There’s an optimal amount of graphene that needs to be added to LFP to get the best results. Too little graphene, and you won’t see a significant improvement. Too much, and it can actually hinder performance or increase costs unnecessarily. Research suggests that around 1% of graphene content is often the sweet spot. This amount is enough to create an effective conductive network without negatively impacting the LFP structure or adding too much weight. Finding this balance is key to creating cost-effective and high-performing batteries using nanomaterials for battery performance.

| Graphene Content (%) | Capacity Increase (vs. pristine LFP) |

|---|---|

| 1% | Up to 9.2% |

| 2% | (Data not shown, but generally plateaus) |

| 4% | (Data not shown, may decrease slightly) |

The integration of graphene into LiFePO4 cathodes creates a more robust electron transport pathway. This network helps to overcome the intrinsic conductivity limitations of LiFePO4, leading to better utilization of the active material and consequently, a higher energy density of graphene LiFePO4.

Graphene Morphology and Its Effect on LiFePO4

So, we’ve talked about how graphene is generally good for LiFePO4 batteries, but it turns out how the graphene looks matters a lot. It’s not just about throwing any old graphene in there; the shape and size play a big role in how well it helps the battery perform.

Large and Curved Graphene for Effective Networks

When you’re trying to build a good conductive path for electrons, bigger and more flexible pieces of graphene seem to do a better job. Think of it like building roads: a few small, straight paths might get you somewhere, but a network of larger, winding highways can handle much more traffic. Large and curved graphene sheets are better at creating a continuous, three-dimensional conductive network around the LiFePO4 particles. This helps electrons move more freely, which is key for getting the most out of the battery material, especially at higher charge and discharge rates. It’s all about making sure every bit of the LiFePO4 can easily connect to the electrical pathway.

Comparing Different Graphene Types and Sizes

Researchers have looked at different kinds of graphene, including ones made in labs and commercially available options. They found that the source and how the graphene was made really changes its properties. For instance, using commercial graphene materials like G V4 and G V20, which have different sizes and shapes, showed varying improvements in capacity compared to pristine LiFePO4. While lab-made graphene might offer some advantages, the focus is shifting towards commercially viable options that can be produced in large quantities. This is important because we want batteries that are not only high-performing but also affordable.

Here’s a quick look at how different graphene types affected capacity at 1 C:

| Graphene Type | Capacity Increase (vs. pristine LFP) |

|---|---|

| LFP/G (home-made) | Up to 9.2% |

| LFP/G V20 (commercial) | Up to 6.9% |

| LFP/G V4 (commercial) | Up to 4.6% |

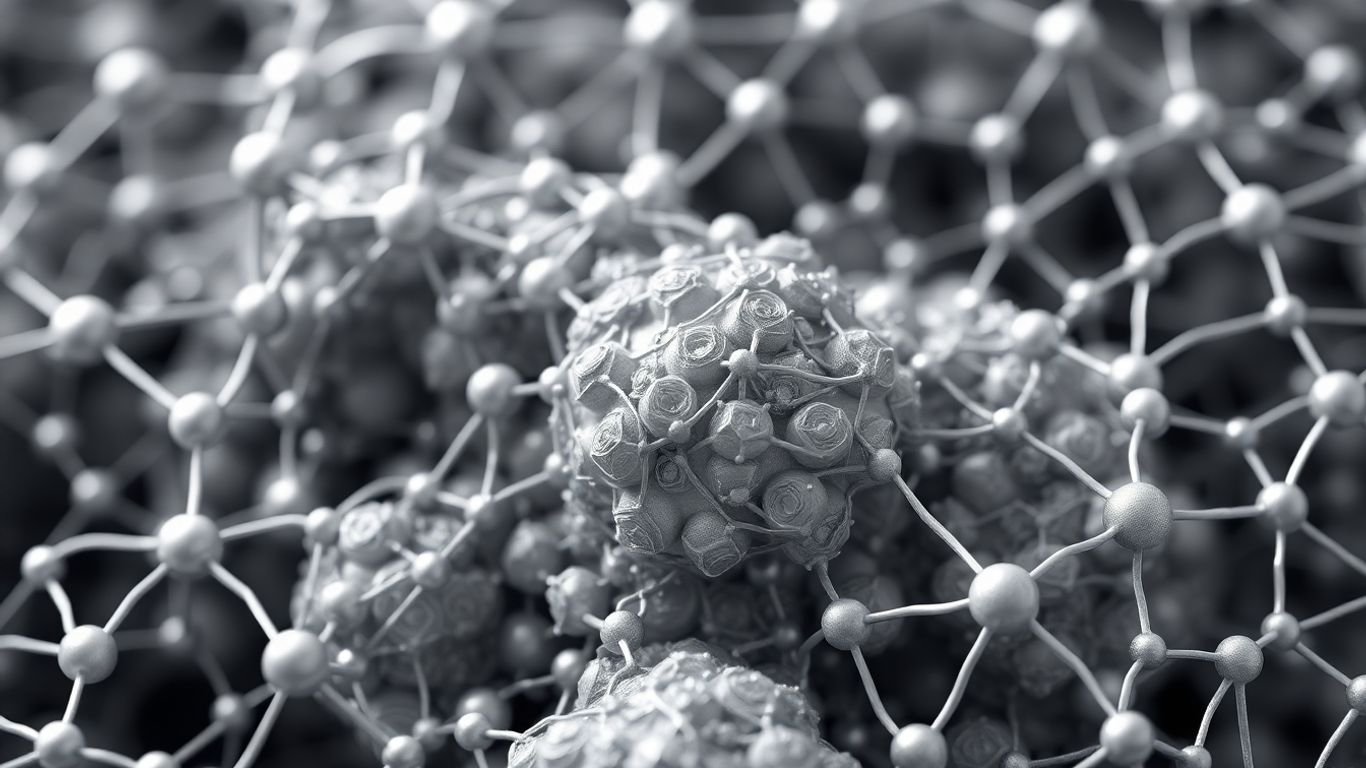

The Importance of Graphene’s Structural Features

It’s not just about having graphene; it’s about its structure. Things like wrinkles, curvature, and the overall size of the graphene flakes influence how well they can form that conductive network. A well-formed network means better contact between the graphene and the LiFePO4 particles, leading to improved electron transport. This is why simply adding graphene isn’t enough; you need to consider its physical characteristics to truly boost battery performance. A good example of this is how a FLG coating can significantly improve contact and conductivity.

The way graphene is structured, its size, and its shape, all contribute to how effectively it can create a conductive web within the battery electrode. This network is what allows for faster and more complete use of the LiFePO4 material, leading to better battery performance overall. It’s a bit like making sure all the ingredients in a recipe are properly mixed to get the best flavor.

Ultimately, understanding these morphological details helps us design better graphene-enhanced LiFePO4 batteries for a wide range of applications.

Addressing Low-Temperature Challenges in LiFePO4

You know, batteries can be a bit finicky when it gets cold. LiFePO4, while great for many things, has always had a bit of a struggle when the temperature drops. It’s like trying to run a marathon in a snowstorm – things just slow down.

Intrinsic Conductivity Limitations of LiFePO4

The main issue is that LiFePO4 itself isn’t the best at conducting electricity, especially when it’s chilly. Think of it like a crowded hallway; it’s hard for everyone to move quickly. This poor conductivity means the battery can’t deliver power as well, which is a real bummer for things like electric cars that need to work reliably even on a frosty morning. We’ve tried adding stuff to help, like conductive powders, but sometimes that messes with the battery’s structure or causes other problems down the line.

Graphene’s Contribution to Low-Temperature Functionality

This is where graphene comes in, and it’s pretty neat. By creating a network of graphene, we can build better pathways for electrons to travel. It’s like opening up extra lanes on that crowded hallway. This improved electron flow is key to making LiFePO4 batteries perform better when it’s cold. The graphene acts as a superhighway, letting electricity zip around much more easily, even when the battery material is being stubborn.

Ternary Conductive Networks for Electron Transport

What’s really interesting is how they’ve designed this graphene network. They’re talking about a ‘ternary point-line-plane’ structure. Basically, it means the graphene forms a complex, interconnected web that covers all the bases. It’s not just a few random connections; it’s a well-organized system that ensures electrons can find the quickest route from one point to another. This kind of structured network is way more effective than just sprinkling in some conductive material. It helps maintain good electron transport across the whole electrode, which is exactly what you need when the temperature dips and everything else is sluggish.

Here’s a quick look at what happens:

- Normal Conditions: Electrons flow reasonably well.

- Low Temperatures: Electron flow gets restricted due to LiFePO4’s inherent properties.

- With Graphene Network: Electrons have clear, efficient pathways, overcoming the low-temperature limitations.

Building these advanced conductive networks is a smart way to get around the natural weaknesses of materials like LiFePO4. It’s about smart design, not just adding more stuff. This approach could really change how we use batteries in different climates.

Scalability and Commercial Viability

So, we’ve talked a lot about how awesome graphene is for making LiFePO4 batteries better. But can we actually make this stuff in big batches without breaking the bank? That’s the million-dollar question, right?

Large-Scale Production of Reduced Graphene Oxide

Making graphene oxide (GO) in huge amounts is actually pretty doable. The common methods, like the modified Hummers method, can be scaled up. The trick is getting consistent quality when you’re talking about tons of material, not just grams in a lab. We’re talking about making sure the GO sheets are the right size and have the right number of oxygen groups, which affects how well it works later on. It’s a bit like baking a giant cake – you need the recipe to be spot on, and the oven to be just right, otherwise, you get a mess.

Utilizing Industrially Sourced Graphene Materials

This is where things get really interesting for commercial use. Instead of making our own graphene, we can buy it from companies that already produce it in bulk. Think of companies that make graphene for other industries; they’ve already figured out how to make it cheaply and in large quantities. We’ve seen that using graphene sourced from industrial manufacturers, like certain types of graphene oxide (e.g., G V4 and G V20), works really well with LiFePO4. The key is finding graphene with the right properties – like being large and a bit wrinkled – that these industrial suppliers can provide consistently. This avoids the hassle and cost of in-house production.

Economic Considerations for Graphene-Enhanced LiFePO4

Okay, let’s talk money. Adding graphene does add to the cost, no doubt. But we need to look at the whole picture. If adding a small amount of graphene – say, around 1% – significantly boosts the battery’s performance, like its capacity and how long it lasts, then the extra cost might be totally worth it. It’s a trade-off. We’re seeing that even with commercial-grade graphene, the performance gains can justify the expense, especially for applications like electric vehicles where battery performance is super important.

Here’s a quick look at how adding a bit of graphene can impact capacity:

| Sample | Capacity (mAh/g) at 1C (approx.) | % Increase over Pristine LFP |

|---|---|---|

| Pristine LFP | 130 | – |

| LFP/G | 142 | 9.2% |

| LFP/G V20 | 139 | 6.9% |

| LFP/G V4 | 136 | 4.6% |

The real challenge isn’t just making graphene, it’s making it affordable and consistent enough to be a standard part of battery manufacturing. When you can buy good quality graphene from existing suppliers and see a clear performance benefit, that’s when commercial viability starts to look much brighter.

Structural Integrity and Electrochemical Stability

Maintaining the LiFePO4 Olivine Structure

So, we’ve been talking a lot about how graphene helps LiFePO4 batteries perform better, especially when it comes to conductivity and power. But what about the actual structure of the LiFePO4 itself? It’s pretty important, right? The whole point of the olivine structure in LiFePO4 is its stability, which is great for safety and how long the battery lasts. When you add graphene, you’re essentially creating a composite material.

The goal is to make sure this new mix doesn’t mess with the LiFePO4’s natural ability to hold onto lithium ions and go through charge and discharge cycles without falling apart. The key is creating a strong bond between the graphene and the LiFePO4 particles. This connection helps support the structure, preventing it from degrading over time. Think of it like reinforcing a building – you want the new materials to work with the old ones, not weaken them.

Graphene’s Influence on Cycling Performance

When you’re constantly charging and discharging a battery, the materials inside go through a lot of stress. This is where graphene really shines. By forming a conductive network, graphene helps electrons move more freely. This means less strain on the LiFePO4 particles during each cycle. Less strain generally translates to better durability. Instead of the particles cracking or breaking down after hundreds or thousands of cycles, they tend to stay more intact.

This improved structural resilience is a big reason why graphene-enhanced LiFePO4 batteries can often last much longer than their counterparts without graphene. It’s not just about getting more power out; it’s about keeping that power available for a longer time. We’ve seen studies where adding graphene significantly boosts the number of cycles a battery can handle before its capacity drops noticeably. For example, some research shows that LiFePO4/graphene composites can maintain over 90% of their initial capacity after 500 cycles, whereas plain LiFePO4 might drop below 80% under similar conditions. This kind of improvement is huge for practical applications.

Avoiding Compromises in Electrode Integrity

It’s easy to get carried away with adding more and more graphene, thinking it will always make things better. But there’s a point where too much can actually be a bad thing. If you overload the electrode with graphene, it can start to take up space that the active LiFePO4 material needs. This can lead to a lower overall capacity because you have less of the actual energy-storing material. Plus, the way the electrode is put together matters.

You need a good balance between the active material, the conductive additives like graphene, and the binder that holds it all together. If the electrode structure isn’t right, it can lead to issues like poor contact between particles or even delamination from the current collector over time. So, finding that sweet spot for graphene content is really important. It’s about creating a synergistic effect, where graphene helps LiFePO4 reach its full potential without negatively impacting the electrode’s physical makeup or its ability to store energy. This careful balance is what allows for high-performance, long-lasting batteries.

Here’s a quick look at how different graphene amounts might affect performance:

| Graphene Content (wt%) | Cycling Stability (Capacity Retention after 500 cycles) | Electrode Density |

|---|---|---|

| 0 | ~85% | High |

| 2 | ~92% | Moderate |

| 5 | ~95% | Moderate |

| 10 | ~93% | Slightly Lower |

| 15 | ~90% | Lower |

The physical arrangement of graphene within the LiFePO4 electrode is just as vital as its presence. A well-distributed graphene network acts as a scaffold, supporting the LiFePO4 particles and preventing mechanical stress during ion insertion and extraction. This structural support is key to preventing capacity fade and ensuring the longevity of the battery cell. Without this careful integration, the benefits of graphene can be short-lived, as the electrode structure itself begins to break down under operational demands.

Wrapping It Up

So, what does all this mean for LiFePO4 batteries? Basically, adding graphene, especially the bigger, curvier pieces, seems to really help these batteries work better, particularly when it’s cold out. We saw better capacity and faster charging/discharging. Plus, using graphene made from industrial sources means this could actually be a cost-effective way to improve batteries for things like electric cars. It looks like about 1% graphene is the sweet spot, giving us good performance without breaking the bank. This research shows a solid path forward for making LiFePO4 batteries more reliable and useful in a wider range of conditions.

Frequently Asked Questions

What is LiFePO4 and why does it need improvement?

LiFePO4, or lithium iron phosphate, is a material used in batteries, kind of like the power source in a toy or a phone. While it’s pretty good, it sometimes has trouble working well when it gets really cold, and it could be faster at charging and discharging. Scientists are trying to make it better so batteries can last longer and work more reliably, especially in electric cars.

How does graphene help LiFePO4 batteries?

Graphene is like a super-thin, super-strong material made of carbon. When mixed with LiFePO4, it creates a special network that helps electricity move around much more easily. Think of it like building wider, smoother roads for cars instead of bumpy, narrow paths. This makes the battery charge and discharge faster and perform better, even in cold weather.

What is ‘reduced graphene oxide’ and why is it important?

Reduced graphene oxide, or rGO, is a form of graphene that’s been treated to make it even better at conducting electricity. Making a lot of this rGO in a way that’s easy and cheap for factories is a big deal. It means we can use this improved material in batteries that are made in large quantities for everyday use, not just in labs.

Why is the shape and size of graphene important?

Not all graphene is the same! Scientists found that graphene pieces that are large and a bit wavy or curved work best. These shapes help create a strong, connected network inside the battery. Smaller, flatter pieces don’t build as good of a network, so the battery doesn’t get as much of a boost.

How much graphene should be added to LiFePO4 batteries?

Adding too much graphene can actually be bad, and adding too little might not help enough. Researchers found that adding about 1% of graphene is the sweet spot. This amount gives the battery a good performance boost without costing too much or making other parts of the battery weaker.

Can these improved LiFePO4 batteries be made in large amounts?

Yes, that’s a key goal! The methods used to make the graphene and mix it with LiFePO4 are designed to be suitable for factories. This means that batteries with these improvements could become common in things like electric cars and other devices in the future, making them more affordable and effective.