Vienna’s Incineration Plant: The Technology Behind Garbage to Green Energy

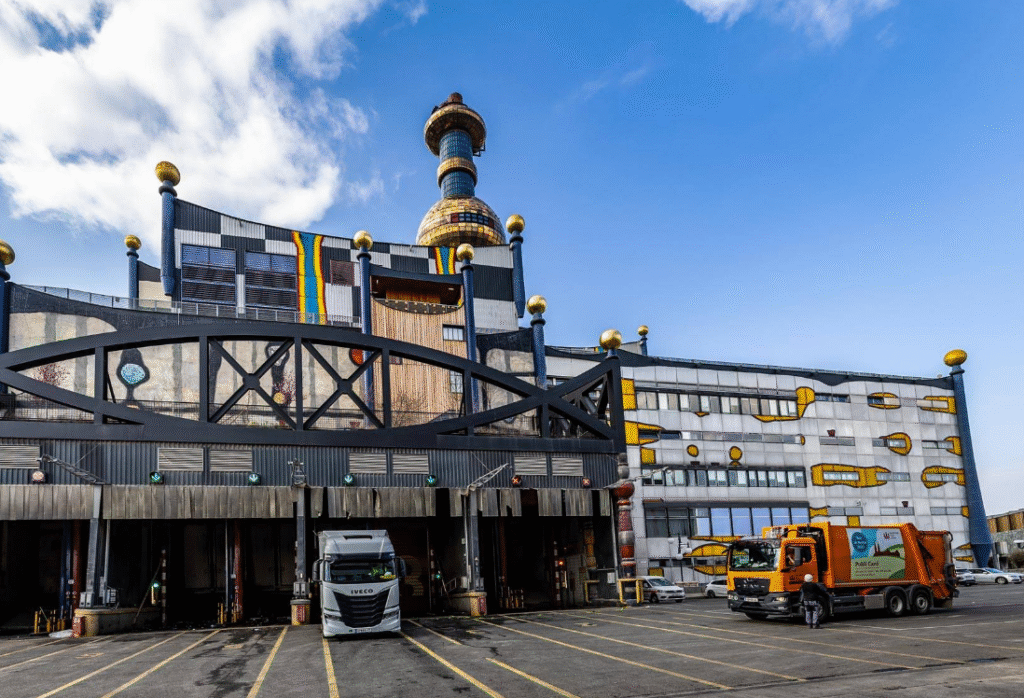

Ever wondered where your trash goes after it’s picked up from the curb? In Vienna, Austria, it could be doing more than just sitting in a landfill—it might be helping to power the city. Vienna’s Incineration Plant, also known as Spittelau, is a striking example of how innovative infrastructure can turn everyday waste into a sustainable energy source.

Far from being just a garbage disposal site, this facility is a vital part of Vienna’s climate-conscious strategy, converting thousands of tons of household refuse into clean heat and electricity for local homes and businesses. What makes it even more unique is its bold, artistic design by the Austrian artist Friedensreich Hundertwasser, blending environmental responsibility with architectural beauty. Vienna’s Incineration Plant proves that effective waste management, green energy production, and urban aesthetics can coexist—and thrive—in a modern city.

Key Takeaways about Vienna’s Incineration Plant

- The Vienna Incineration Plant is a prime example of how a city can manage its own waste, from collection to energy production, keeping everything in-house.

- The Spittelau plant, with its unique design by Friedensreich Hundertwasser, proves that industrial facilities can also be works of art and even tourist spots.

- Each year, the Vienna Incineration Plant processes around 250,000 tons of household waste, producing electricity and district heating for thousands of homes.

- Modern waste-to-energy facilities like the Vienna Incineration Plant operate under strict environmental rules, making them a clean way to handle trash, unlike older methods.

- Vienna’s long-term planning for waste management, including involving the public and experts, has helped make projects like the Pfaffenau plant successful and widely accepted.

The Vienna Incineration Plant: A Model for Sustainable Waste Management

Vienna’s Commitment to Independent Waste Processing

Vienna takes waste management seriously, handling the entire process from collection to treatment and disposal. This commitment to independence ensures control over waste streams and promotes efficient resource recovery. The city’s approach highlights a dedication to managing its waste responsibly and sustainably. It’s pretty cool how they handle everything themselves, making sure nothing slips through the cracks. This also allows them to adapt quickly to new challenges and opportunities in the waste management sector.

Integrating Waste Management into Urban Infrastructure

Vienna’s waste-to-energy plants aren’t just functional; they’re integrated into the city’s fabric. The Spittelau plant, for example, is a landmark, not an eyesore. This integration shows how waste management can be part of the urban landscape. It’s not hidden away but celebrated as a key part of the city’s infrastructure. The city draws up a waste management plan every six years and tries to involve all important stakeholders in the process: politicians, experts and environmental groups. Outlining the experiences gained, Ableidinger says: “This has enabled us to reach agreement on important projects in Vienna during the planning stage and to prevent subsequent protests. One example is the construction of Vienna’s third waste incineration plant, Pfaffenau, which was opened in 2008.”

Public Acceptance of Thermal Recycling

Vienna has achieved high public acceptance of its thermal recycling facilities. This acceptance is due to factors like architectural design, strict emission controls, and community engagement. People trust the system because they see it working and understand the benefits. It’s a testament to how transparency and good design can change public perception. The waste-to-energy process in Vienna incineration plant is widely accepted by the public.

Vienna’s success in waste management stems from a combination of technological innovation, architectural integration, and public engagement. This holistic approach has transformed waste disposal into a sustainable energy source, making Vienna a leader in urban sustainability.

Architectural Innovation and Environmental Stewardship at Spittelau

Hundertwasser’s Artistic Redesign of the Vienna Incineration Plant

Okay, so the Spittelau plant wasn’t always the colorful masterpiece it is today. After a fire in 1987, instead of just tearing it down, Vienna decided to rebuild and give it a serious makeover. They brought in Friedensreich Hundertwasser, an artist known for his quirky and nature-friendly designs, and he transformed the utilitarian building into something truly unique. It’s like he threw a rainbow at it – irregular shapes, bright colors, and a golden ball on top of the chimney. It’s hard to believe it’s actually a waste incineration plant!

Combining Art, Energy, and Waste Management

What’s cool about Spittelau is how it blends art with its main job: dealing with waste and making energy. It’s not just a pretty face; it’s a functional facility that processes a ton of waste each year. The plant handles about 250,000 tons of household waste annually, turning it into electricity and district heating. It’s a great example of how you can integrate essential infrastructure into the urban landscape in a way that’s actually pleasing to look at. The new incinerator technology makes this possible.

Spittelau as a Tourist Attraction and Educational Hub

Believe it or not, Spittelau is a tourist attraction! People come from all over to see Hundertwasser’s design and learn about Vienna’s approach to waste management. You can even take a tour of the plant to see how it all works. It’s educational, showing how waste is recycled and turned into energy. Plus, it challenges the idea that waste facilities have to be ugly and hidden away. It’s a symbol of Vienna’s commitment to sustainability and innovation.

The Spittelau plant demonstrates that industrial facilities can be both functional and aesthetically pleasing, contributing positively to the urban environment and public perception of waste management.

Powering Vienna: Energy Production at the Spittelau Plant

The Spittelau plant isn’t just a pretty face; it’s a powerhouse that significantly contributes to Vienna’s energy needs. It’s a prime example of how Vienna turns garbage into clean energy, turning what would otherwise be waste into a valuable resource.

Annual Waste Processing Capacity of the Vienna Incineration Plant

Each year, the Spittelau plant processes around 250,000 tons of household waste. This massive amount of waste is not just eliminated; it’s transformed into energy, showcasing Vienna’s commitment to sustainable energy Austria.

Electricity and District Heating Generation

The plant generates approximately 40,000 MWh of electricity and 470,000 MWh of district heating Vienna annually. To put that into perspective, that’s enough to heat over 60,000 households in Vienna each year. It’s a pretty big deal for the city’s energy infrastructure.

Resource Recovery: Scrap Iron and Clinker

Beyond electricity and heat, the Spittelau plant also recovers valuable materials. The process yields about 6,000 tons of scrap iron and 60,000 tons of clinker, ash, and filter cake. These materials can then be reused in various applications, further minimizing waste and maximizing resource efficiency.

The Spittelau plant exemplifies a closed-loop system where waste is minimized, energy is generated, and valuable materials are recovered. This approach not only reduces the burden on landfills but also contributes to a more sustainable and resource-efficient urban environment.

Here’s a quick breakdown of the plant’s output:

- Waste Processed: ~250,000 tons/year

- Electricity Generated: ~40,000 MWh/year

- District Heating: ~470,000 MWh/year

- Scrap Iron Recovered: ~6,000 tons/year

- Clinker, Ash, etc.: ~60,000 tons/year

Advanced Technology in Waste-to-Energy Facilities

Modern Incineration: Beyond Past Misconceptions

It’s easy to think of incineration as an old, dirty process, but modern waste-to-energy (WTE) facilities are nothing like the open burning of the past. These plants use advanced technologies to minimize environmental impact and maximize energy recovery. The old image of smoke-belching incinerators is outdated; today’s facilities are highly regulated and designed to operate cleanly and efficiently.

Strict Emission Requirements for the Waste Industry

One of the biggest advancements in WTE technology is the focus on emission control. The waste industry faces some of the strictest emission requirements around. This means plants must use sophisticated systems to clean flue gas before it’s released into the atmosphere. These systems often include:

- Charcoal filters to remove heavy metals.

- Scrubbers to neutralize acidic gases.

- Particulate filters to capture dust and soot.

These measures significantly reduce the amount of pollutants released, making modern WTE plants much cleaner than older incinerators. It’s a night-and-day difference.

The Role of Waste-to-Energy in a Circular Economy

WTE plays a key role in a solid waste management system by turning trash into a resource. Instead of just burying waste in landfills, WTE plants extract energy in the form of electricity and heat. Plus, they can recover valuable materials like scrap iron. Consider these points:

- Reduces landfill volume.

- Generates renewable energy.

- Recovers valuable materials.

| Material | Recovery Potential (tons/year) |

|---|---|

| Scrap Metal | Up to 700,000 |

This approach aligns with the principles of a circular economy, where waste is minimized and resources are reused as much as possible. WTE helps close the loop by transforming waste into useful products and energy.

Global Context: Vienna Incineration Plant Among Leading Facilities

Comparing Spittelau with International Waste-to-Energy Plants

The Spittelau incineration plant isn’t just a local success story; it’s a player on the global stage. When you stack it up against other waste-to-energy facilities around the world, a few things stand out. First, there’s the architectural aspect. How many waste plants can you name that are also tourist attractions? Hundertwasser’s redesign really sets it apart. Beyond aesthetics, its technology and integration into the city’s infrastructure are noteworthy. Many plants focus solely on waste disposal, but Spittelau combines that with significant energy production and district heating.

District Heating Contributions of Major Incineration Plants

District heating is a big deal, especially in colder climates. Here’s a quick look at how Spittelau compares to other major incineration plants in terms of district heating contributions:

| Plant Name | Location | District Heating Output (MWh/year) |

|---|---|---|

| Spittelau | Vienna, Austria | 470,000 |

| Amager Bakke | Copenhagen | (Data Unavailable) |

| (Hypothetical) Plant X | (Example City) | 350,000 |

| (Hypothetical) Plant Y | (Example City) | 500,000 |

As you can see, Spittelau holds its own, providing heat to a significant portion of Vienna. The 2020 packaging waste flows in Austria show how important these plants are.

The Future of Waste-to-Energy Technology

Waste-to-energy tech is only going to become more important. As cities grow and waste increases, finding sustainable solutions is critical. The future likely involves:

- More efficient incineration processes to maximize energy output.

- Better emission control technologies to minimize [Vienna incineration plant environmental impact].

- Increased focus on resource recovery, like extracting valuable metals from ash.

- Integration with smart grids for optimized energy distribution.

The key is public acceptance. Plants like Spittelau have shown that by combining functionality with art and community engagement, it’s possible to overcome the

Strategic Planning for Vienna’s Waste Infrastructure

Long-Term Waste Management and Prevention Plans

Vienna takes a proactive approach to waste management, crafting a new waste management and prevention plan every six years. This plan is designed to anticipate future challenges and opportunities in the waste sector. The city’s commitment to urban waste management solutions is evident in its detailed planning processes.

Stakeholder Involvement in Project Development

Vienna actively involves various stakeholders—politicians, experts, and environmental groups—in the development of its waste management projects. This inclusive approach helps to build consensus and prevent potential conflicts down the line. It’s a pretty smart way to get everyone on board, honestly.

By including diverse perspectives, Vienna ensures that its waste management strategies are both effective and publicly supported. This collaborative model has proven successful in gaining acceptance for even potentially controversial projects.

The Successful Development of the Pfaffenau Plant

The Pfaffenau plant serves as a prime example of Vienna’s successful strategic planning. The project’s initial preparations began roughly a decade before construction even started. This foresight allowed for thorough planning and stakeholder engagement, leading to a smooth development process. The waste-to-energy incinerators are a key part of this.

Here’s a quick look at the timeline:

- Initial Planning: 10 years prior to construction

- Stakeholder Engagement: Ongoing throughout the planning phase

- Construction: Followed after extensive preparation

- Opening: 2008

This approach highlights the importance of long-term vision and collaboration in implementing complex infrastructure projects. The Friedensreich Hundertwasser designed waste facility is another example of Vienna’s innovative approach.

Wrapping It Up

So, what’s the big takeaway here? Vienna’s Spittelau plant really shows how you can turn something like trash into a good thing for the city. It’s not just about getting rid of waste; it’s about making power, heating homes, and even looking pretty while doing it. This whole setup proves that with some smart thinking and good design, we can handle our waste in a way that helps the environment and gives us energy too. It’s a pretty neat example of how cities can be more self-sufficient and green at the same time.

Frequently Asked Questions

How much trash does the Vienna plant handle?

The Spittelau plant in Vienna burns about 250,000 tons of household trash each year. This process creates enough electricity and heat for many homes.

Does the plant make electricity and heat?

Yes, the Spittelau plant makes both electricity and heat. It produces enough heat to warm over 60,000 homes in Vienna every year.

What else does the plant get from the trash?

The Spittelau plant also recovers useful materials like scrap iron and a rocky material called clinker from the burned trash.

What makes the Spittelau plant unique?

The Spittelau plant is special because it was redesigned by a famous artist named Friedensreich Hundertwasser. It has a colorful look, a golden ball on its chimney, and plants growing on its roof. It’s a mix of art, energy, and waste management.

What is waste-to-energy technology?

Burning trash for energy, also known as waste-to-energy, is a way to turn garbage into power. Modern plants like Vienna’s have strict rules to keep the air clean, unlike older methods that caused more pollution.

Why are waste-to-energy plants important?

Waste-to-energy plants are important because they help manage trash, create energy, and recover materials. They are a part of a bigger plan to reduce waste and use resources wisely.

3 Comments