Waste to Energy Incinerator Technology: Innovations and Future Trends

Waste to energy incinerator systems are becoming a key part of our waste management and energy production strategies. These facilities help cut down on landfill use while generating electricity from materials we can’t recycle. With new technologies and methods emerging, the waste to energy incinerator field is evolving rapidly. In this article, we will explore the latest innovations, current trends, and future directions in waste to energy incinerator technology, as well as the environmental and economic impacts they carry.

What Is a Waste to Energy Incinerator?

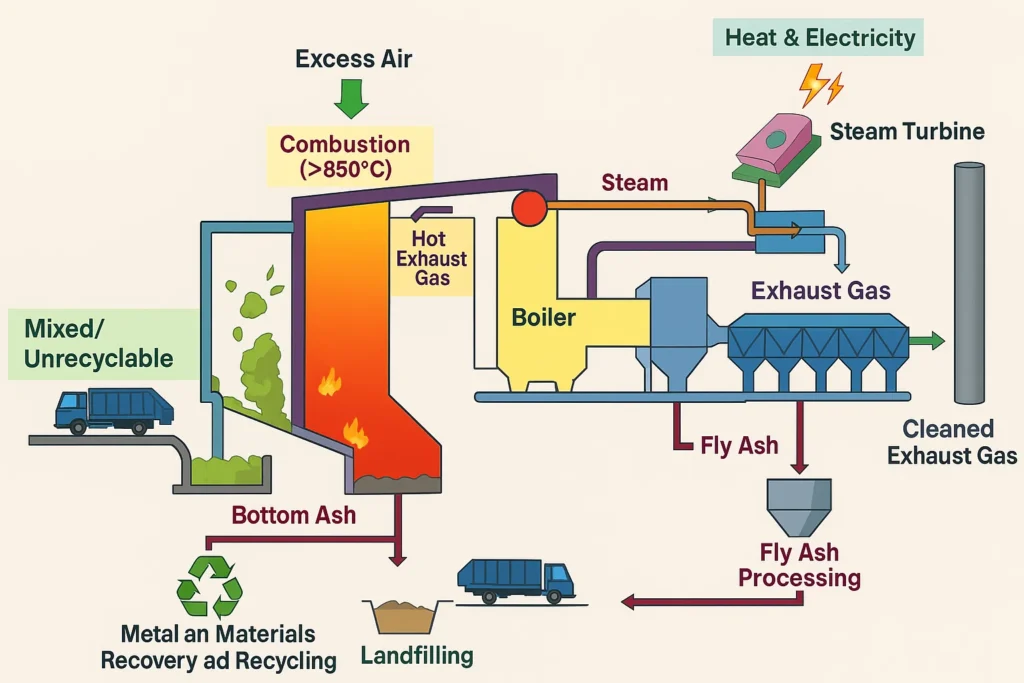

A waste to energy incinerator is a facility that burns municipal solid waste to generate electricity or heat. These incinerators play a dual role in modern waste management strategies—reducing landfill volume and producing usable energy. With growing interest in sustainable practices, understanding how these systems work is more important than ever.

Key Takeaways

- Waste-to-energy incinerators are evolving with new technologies like advanced combustion systems and plasma gasification.

- Current trends include integrating carbon capture and using AI for better operations in waste management.

- Innovations are focused on improving fuel efficiency and reducing harmful emissions from incinerators.

- Environmental concerns are being addressed through better pollution control and community education efforts.

- The future of waste-to-energy technology looks promising with advancements aimed at sustainability and efficiency.

Innovations In Waste To Energy Incinerator Technology

Waste to energy (WtE) incinerator tech has come a long way. It’s not just about burning trash anymore; it’s about doing it smarter, cleaner, and more efficiently. The goal is to minimize environmental impact while maximizing energy recovery. Let’s look at some of the key innovations.

Advanced Combustion Systems

These systems are designed to optimize the burning process, ensuring that waste is completely combusted. This leads to reduced emissions and increased energy output. Advanced combustion systems use technologies to carefully control temperature, airflow, and residence time, resulting in a cleaner and more efficient process.

- Precise temperature control for complete combustion.

- Optimized airflow to minimize emissions.

- Extended residence time to ensure thorough burning.

These systems represent a significant step forward in making waste incineration a more environmentally sound option. They address many of the concerns about pollution and emissions that have historically been associated with waste incineration.

Waste-To-Energy Plants

WtE plants are facilities that convert waste into usable energy, such as electricity, heat, or fuel. These plants play a crucial role in sustainable waste management by reducing the amount of waste that ends up in landfills. They’re becoming more common, and are a key part of modern waste strategies. Plus, they can be surprisingly cost-effective waste to energy incinerator systems for small cities.

- Electricity generation for local grids.

- Heat production for district heating systems.

- Fuel production for transportation or industrial use.

Plasma Gasification Techniques

Plasma gasification is a cutting-edge technology that uses extremely high temperatures to convert waste into syngas (synthetic gas). This gas can then be used to generate electricity or produce other valuable products. It’s like turning trash into treasure, and it’s a pretty cool process. It’s a great way to understand how waste to energy incinerators reduce landfill waste.

- High-temperature conversion of waste into syngas.

- Syngas used for electricity generation.

- Production of other valuable products from syngas.

| Feature | Traditional Incineration | Plasma Gasification |

|---|---|---|

| Temperature | Lower | Very High |

| Waste Types | Limited | Wide Range |

| Emissions | Higher | Lower |

| By-products | Ash | Syngas |

Current Trends In Waste To Energy Incineration

Integration Of Carbon Capture

Okay, so carbon capture is becoming a big deal in waste-to-energy. Basically, we’re trying to grab the carbon dioxide that’s produced when we burn trash and store it so it doesn’t go into the atmosphere.Though still relatively new, pilot projects are popping up all over. While not perfect, the approach marks a step in the right direction It’s all about making waste disposal units more sustainable.

Artificial Intelligence In Operations

AI is making its way into pretty much everything, and waste-to-energy is no exception. We’re talking about using AI to optimize the whole incineration process. Think about it: AI can analyze tons of data to figure out the best way to burn different types of waste, predict when equipment might fail, and even adjust operations in real-time to minimize emissions. It’s like having a super-smart engineer constantly tweaking things to make the plant run better. This leads to increased efficiency and reduced downtime.

Here’s a quick look at some potential AI applications:

- Predictive maintenance to avoid breakdowns.

- Optimized combustion for cleaner emissions.

- Automated waste sorting for better fuel.

The integration of AI in waste-to-energy plants is not just about automation; it’s about creating a smarter, more responsive system that can adapt to changing waste streams and environmental regulations. It’s a long-term investment in the future of sustainable waste management.

Enhanced Waste Sorting Technologies

Before you can even burn the trash, you gotta sort it, right? Well, that’s where enhanced waste sorting technologies come in. We’re talking about using advanced sensors, robotics, and AI to separate recyclable materials from the stuff that’s actually going to be incinerated. This not only makes the incineration process more efficient, but it also helps to recover valuable resources that would otherwise be lost. It’s a win-win. This is a great way to improve trash collection services and reduce the amount of waste that ends up in landfills.

Here’s a simple comparison of old vs. new sorting methods:

| Feature | Traditional Sorting | Enhanced Sorting |

|---|---|---|

| Accuracy | Lower | Higher |

| Speed | Slower | Faster |

| Material Recovery | Less | More |

| Labor Costs | Higher | Lower |

Advancements In Fuel Utilization And Emission Control

Annual Fuel Utilization Efficiency

Okay, so, when we talk about making waste-to-energy plants better, a big part of that is getting more bang for your buck, right? That’s where Annual Fuel Utilization Efficiency (AFUE) comes in. Basically, it’s a measure of how well an incinerator turns waste into usable energy, like heat or electricity. The higher the AFUE, the less waste and the more energy we get.

Think of it like this:

- Old incinerators: Low AFUE, lots of wasted energy.

- New incinerators: High AFUE, less waste, more power.

- Future incinerators: Even higher AFUE, super efficient!

Synthetic Fuel Production

Another cool thing happening is turning waste into synthetic fuels. Instead of just burning trash, we can actually convert it into something useful like synthetic diesel or methanol. These fuels can then be used for transportation or other industrial processes. It’s like taking trash and turning it into gold, or at least something that can power your car. This process can help reduce our reliance on fossil fuels and create new investment opportunities.

Emission Reduction Technologies

Of course, none of this matters if we’re just creating more pollution. That’s why emission reduction technologies are super important. We’re talking about things like:

- Carbon capture systems: Grabbing CO2 before it goes into the atmosphere.

- Advanced filters: Removing harmful particles from the exhaust.

- Better combustion processes: Burning waste more cleanly in the first place.

By focusing on these technologies, we can make waste-to-energy plants much cleaner and more sustainable. It’s not just about getting rid of trash; it’s about doing it in a way that doesn’t harm the environment. We need to make sure that waste incinerators are part of the solution, not part of the problem.

Addressing Environmental Concerns In Waste To Energy Incineration

Waste-to-energy (WtE) incineration offers a way to reduce landfill waste, but it also brings up environmental worries. It’s a balancing act to make sure these plants are as clean and sustainable as possible. Let’s look at how the industry is tackling these challenges.

Pollution Control Measures

Incinerators have gotten a lot better at controlling pollution. Modern facilities use advanced filtration systems to capture harmful pollutants before they’re released into the air. These systems often include:

- Fabric filters (baghouses) to remove particulate matter.

- Scrubbers to neutralize acid gases like sulfur dioxide and hydrogen chloride.

- Selective catalytic reduction (SCR) to reduce nitrogen oxides (NOx).

These technologies significantly cut down on emissions, making WtE plants much cleaner than older models. The goal is to meet and exceed environmental regulations, protecting air quality and public health. For example, waste incinerators are now equipped with continuous emission monitoring systems (CEMS) to ensure compliance.

Sustainable Waste Management Practices

It’s not just about cleaning up emissions; it’s also about managing waste in a more sustainable way. This includes:

- Reducing the amount of waste sent to incinerators through better recycling programs.

- Pre-treating waste to remove materials that could cause problems during incineration.

- Recovering valuable materials from the ash produced by the process.

By integrating WtE into a broader waste management strategy, we can minimize environmental impact and maximize resource recovery. This approach sees incineration as one part of a larger system, not a standalone solution.

Community Engagement And Education

One of the biggest challenges is often public perception. People worry about the potential health and environmental effects of incinerators. To address this, it’s important to:

- Engage with the community to explain how modern WtE plants operate and the safeguards in place.

- Provide transparent data on emissions and environmental performance.

- Address concerns and answer questions openly and honestly.

Building trust and understanding is key to gaining community support for WtE projects. Education can help people see the benefits of energy recovery and how it fits into a sustainable waste management plan.

Future Directions For Waste To Energy Incinerator Technology

Waste-to-Energy (WtE) is heading toward some interesting changes. It’s not just about burning trash anymore; it’s about making the process cleaner, more efficient, and more sustainable. Think of it as upgrading from a clunky old car to a sleek, eco-friendly vehicle. The future of waste incineration is looking brighter than ever.

Improving Efficiency And Reducing Emissions

Future WtE tech needs to focus on getting better at what it does. That means upping efficiency, cutting down on emissions, and building infrastructure that doesn’t leak and doesn’t cost a fortune to maintain. We’re talking about making these plants run smoother, cleaner, and cheaper.

- Better combustion systems that burn waste more completely.

- Advanced filters to catch even the tiniest pollutants.

- Using AI to tweak the process in real-time for maximum efficiency.

The goal is to make WtE plants so clean and efficient that they become a normal part of the energy landscape, not just a last resort for dealing with trash.

Infrastructure Development For Sustainability

Building the right infrastructure is key. It’s not just about slapping up a plant; it’s about creating a system that works for the long haul. This includes everything from how waste is collected to how the energy is distributed. Think about it like building a house – you need a solid foundation, good plumbing, and reliable electricity.

- Investing in modern WtE facilities.

- Upgrading existing plants with new tech.

- Creating waste sorting facilities to remove recyclables before incineration.

Innovative Waste Processing Methods

There are some cool new ways to process waste that could change the game. Gasification is one of them. Instead of just burning everything, gasification turns waste into a synthetic gas (syngas) that can be used as fuel. It’s like turning trash into treasure. The Asia-Pacific region is expected to see substantial growth in this area.

- Gasification: A thermal WtE method that’s generally considered a much better alternative to incineration, as its product (syngas) gets cleaned before (rather than after) use.

- Plasma gasification: Uses extremely high temperatures to break down waste into its basic elements.

- Anaerobic digestion: Uses microorganisms to break down organic waste, producing biogas that can be used for energy.

Global Perspectives On Waste To Energy Incineration

Case Studies From Leading Countries

Okay, so let’s talk about how different countries are handling waste-to-energy (WtE) incineration. It’s not a one-size-fits-all situation, and what works in one place might not in another. For example, some European countries, like Sweden and Denmark, have been doing this for ages and are super advanced. They’ve got really strict environmental regulations and have managed to integrate WtE into their overall energy systems pretty well. On the other hand, you’ve got countries like Japan, where space is a major issue, so they’ve had to get creative with their WtE plants, often building them right in the middle of cities. Each country’s approach reflects its unique circumstances and priorities.

- Sweden: High efficiency, district heating integration.

- Japan: Compact designs, advanced pollution control.

- Germany: Focus on waste sorting and pre-treatment.

It’s interesting to see how cultural attitudes and government policies play such a big role in how WtE is implemented. Some countries are all-in on it, while others are still hesitant due to concerns about emissions and public perception.

Regulatory Frameworks And Policies

Regulatory frameworks are a big deal when it comes to WtE. Without clear rules and guidelines, things can get messy real quick. Different countries have different standards for emissions, waste handling, and plant operations. The European Union, for instance, has pretty strict directives that member states have to follow, which has pushed them to adopt cleaner and more efficient technologies. Meanwhile, in other parts of the world, the regulations might be more relaxed, which can lead to some questionable practices. It’s all about finding the right balance between encouraging WtE development and protecting the environment. Carbon capture systems reduce greenhouse gas emissions from waste incineration, making it a more sustainable option.

Cultural Attitudes Towards Waste Management

Cultural attitudes? Yeah, they matter a lot more than you might think. How people view waste and its management can really impact the success of WtE projects. In some cultures, there’s a strong emphasis on recycling and reducing waste at the source, which can make it harder to get support for incineration.

People might see it as a last resort, rather than a viable solution. On the flip side, in places where landfill space is running out and there’s less emphasis on recycling, WtE might be seen as a more attractive option. It really comes down to education and communication. If people understand the benefits of WtE and trust that it’s being done safely and responsibly, they’re more likely to get on board. Here’s a few points to consider:

- Public perception of incineration risks.

- Emphasis on waste reduction and recycling.

- Community engagement and education initiatives.

Economic Impacts Of Waste To Energy Incineration

Cost-Benefit Analysis

Waste-to-energy (WtE) incineration presents a complex economic picture. The initial costs to build these plants can be pretty high, but the long-term savings can be significant. WtE facilities reduce the amount of waste going to landfills, which lowers landfill costs and extends the life of existing landfill sites.

Consider these points:

- Reduced landfill usage fees.

- Revenue from electricity or heat sales.

- Potential for government subsidies and incentives.

It’s important to remember that a full cost-benefit analysis needs to consider the environmental impact of waste to energy incinerator facilities, including emissions and potential health effects. These factors can influence the overall economic viability of a project.

Job Creation In The WtE Sector

The WtE sector can be a source of new jobs. These jobs range from construction and operation of the plants to maintenance and management roles. The creation of these jobs can have a positive impact on local economies. Here’s a breakdown:

- Construction jobs: Temporary but significant during the building phase.

- Operational jobs: Long-term positions for plant operation and maintenance.

- Support jobs: Including waste collection, transportation, and administrative roles.

Investment Opportunities And Challenges

Investing in WtE incineration can be a mixed bag. There are opportunities for financial returns, but also significant challenges to consider. The cost and benefits of waste to energy incinerator plants are often weighed carefully by investors.

Here are some challenges:

- High initial capital investment.

- Regulatory hurdles and permitting processes.

- Public perception and concerns about emissions.

Despite these challenges, the potential for long-term revenue generation and the increasing need for sustainable waste management solutions make WtE an interesting area for investment. With advancements in technology and more stringent environmental regulations, the economic landscape of WtE is constantly evolving.

Looking Ahead: The Future of Waste-to-Energy

As we wrap up our look at waste-to-energy incinerator technology, it’s clear that this field is evolving fast. Innovations like gasification and carbon capture are changing the game, making waste management cleaner and more efficient. Sure, there are still challenges to tackle, like emissions and the need for better sorting of waste. But with ongoing advancements, we’re moving toward a future where waste isn’t just trash—it’s a valuable resource. Communities can benefit from reduced landfill use and cleaner energy. So, while we’re not quite there yet, the path ahead looks promising. Let’s keep an eye on these trends and see how they shape our approach to waste and energy in the years to come.

Frequently Asked Questions

What is waste-to-energy technology?

Waste-to-energy technology is a way to turn trash into energy. It usually involves burning waste to create heat, which can then be used to generate electricity.

How does incineration work in waste-to-energy systems?

In incineration, waste is burned at high temperatures. This process reduces the amount of waste and produces heat that can be used to create steam and generate electricity.

What are the environmental benefits of waste-to-energy?

Waste-to-energy helps reduce the amount of waste sent to landfills, which is better for the environment. It also generates energy from materials that would otherwise be wasted.

Are there any harmful emissions from waste-to-energy plants?

Yes, there can be emissions from waste-to-energy plants. However, new technologies are being developed to reduce these emissions and make the process cleaner.

What innovations are being made in waste-to-energy technology?

Innovations include advanced combustion systems that burn waste more efficiently and technologies like plasma gasification that convert waste into gas for energy.

How can communities benefit from waste-to-energy plants?

Communities can benefit from waste-to-energy plants by reducing waste disposal costs, generating local energy, and creating jobs in the waste management sector.

5 Comments