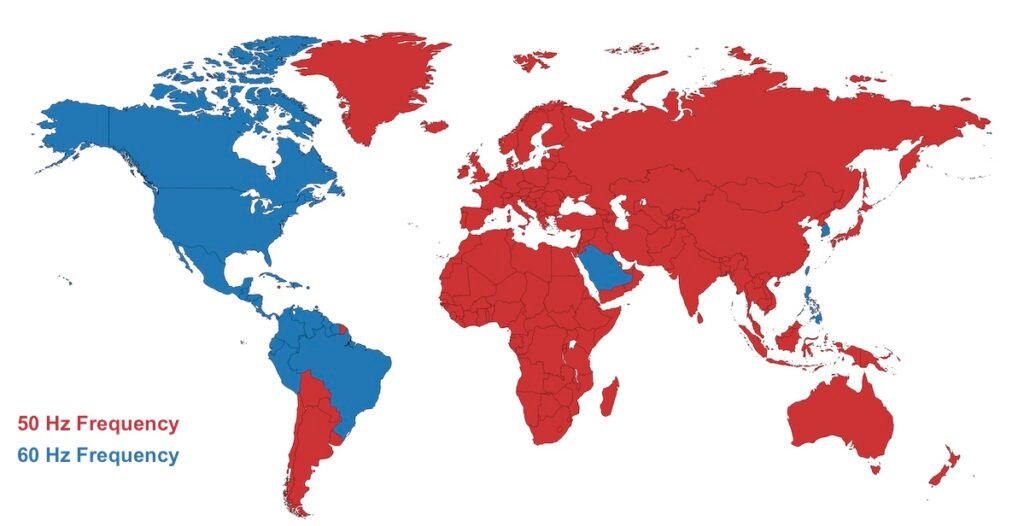

Where do they use 60 hz power

Ever wonder why some countries run on 50 Hz and others on 60 Hz? It’s a bit of a historical quirk, really. Back when electricity was just starting out, different companies and engineers made choices that stuck. These decisions were based on what worked best with the technology available then, like lighting and early motors. Today, this difference means some parts of the world are on one standard, and others are on another. It even affects things like how a diesel generator might perform if you move it between regions.

Key Takeaways

- The split between 50 Hz and 60 Hz power systems is largely due to historical decisions made by early electrical pioneers and manufacturers like Westinghouse and AEG.

- North America, Japan (partially), and parts of South America primarily use 60 Hz, while most of Europe, Asia, and Africa use 50 Hz.

- Early choices were influenced by the needs of lighting systems and the development of induction motors, with 60 Hz being favored by Westinghouse for slightly better performance with arc lighting and smaller transformers.

- Some industrial plants and specialized applications, like aviation, use much higher frequencies (e.g., 400 Hz) for specific benefits like smaller equipment size, but these are not used for long-distance transmission.

- Legacy systems and the immense cost of re-wiring entire national grids are major reasons why the 50 Hz and 60 Hz standards continue to coexist.

Global Adoption of 60 Hz Power

It’s interesting how different parts of the world ended up with different electrical frequencies, isn’t it? For 60 Hz power, a big chunk of the globe uses it, and it really comes down to historical choices made way back when electricity was just getting started.

North American Electrical Standards

In North America, 60 Hz really took hold. Think about Westinghouse and their early work; they were big proponents of 60 Hz. It was seen as a good balance for the equipment they were developing, especially for lighting and motors. This frequency allowed for slightly smaller and lighter transformers, which was a big deal for building out the extensive power grids across the United States and Canada. Most of the continent runs on this standard today, powering everything from homes to massive industrial operations.

South American Grid Unification

South America’s story is a bit more mixed, but many countries eventually settled on 60 Hz. Brazil, for instance, had a period where different regions used different frequencies, partly due to importing equipment from both Europe and the US. A government push in the mid-20th century aimed to unify the grid, and 60 Hz was chosen as the standard, largely because it aligned with the more industrialized areas. This transition wasn’t overnight; it took years to convert everything. Mexico also made a similar shift, moving from 50 Hz to 60 Hz grids during the 1970s to standardize operations.

Japanese Dual Frequency Systems

Japan presents a unique case. The country ended up with two different frequencies: 50 Hz in the eastern part, around Tokyo, and 60 Hz in the western part, near Osaka. This split happened because the initial power generators were purchased from different international suppliers – AEG from Germany (50 Hz) and General Electric from the US (60 Hz). To manage this difference, Japan has special converter stations that can change the frequency between the two grids. This setup is pretty remarkable, especially when you think about powering facilities with generators or needing reliable emergency power supply systems that must match the local grid frequency.

The choice of 60 Hz in North America was influenced by factors like the desire for slightly smaller transformers and a perceived compatibility with timekeeping. This early decision had long-lasting effects, shaping the electrical infrastructure for over a century.

Here’s a quick look at where 60 Hz is commonly found:

- North America (USA, Canada, Mexico)

- Parts of South America (e.g., Brazil, Colombia, Venezuela)

- Parts of Asia (e.g., Japan’s western region, South Korea, Philippines)

When considering 60hz generator applications, it’s important to remember that while generators can sometimes be adjusted to different frequencies, it’s not always a simple swap. Changing a generator’s frequency often means adjusting the engine speed, which can affect its overall power output. This is a key consideration for backup power and powering facilities with generators where consistency is key.

Historical Roots of Frequency Standards

Back in the late 1800s, electricity was a brand new thing, and honestly, nobody really knew what frequency to stick with. It was a bit of a free-for-all, with different places using all sorts of frequencies. Think of it like early cell phones – everyone had a different model and a different way of doing things.

Early European Frequency Choices

In Europe, especially in Germany, companies like AEG started leaning towards 50 Hz. This seemed like a good middle ground. The big machines they used back then, like steam engines and water turbines, naturally spun at speeds that worked well with 50 cycles per second. This frequency also played nicely with the big, clunky transformers and motors of the time. Plus, for the early arc lamps used for lighting, 50 Hz meant a less noticeable flicker, which was a pretty big deal for making streets and factories brighter.

Westinghouse’s 60 Hz Decision

Meanwhile, over in the United States, engineers at Westinghouse were pushing for 60 Hz. Their thinking was that 60 Hz allowed for slightly smaller and lighter transformers, which saved money when building the vast power grids across the country. It also had a neat connection to the 60-second clock, making some electrical calculations a bit simpler. Thanks in part to Nikola Tesla’s alternating current system, Westinghouse really cemented 60 Hz as the U.S. standard by the 1890s, especially after big projects like the Niagara Falls power plant.

The Impact of Early Lighting and Motor Needs

So, why the split? It really came down to what people needed electricity for back then. Early on, lighting was a major driver. For incandescent bulbs, higher frequencies were generally better to avoid visible flicker. However, for early electric motors, lower frequencies like 25 Hz were sometimes preferred because they could handle heavier loads more efficiently. This created a bit of a tug-of-war.

Companies had to choose a frequency that best served their primary customers, whether that was homes needing light or factories needing power for machinery. The choices made by these early pioneers, influenced by the technology available and the specific needs of their markets, are why we still see this 50 Hz and 60 Hz divide today. It’s a fascinating example of how early technological decisions can have a long-lasting impact on global infrastructure.

The initial lack of standardization meant that electrical equipment wasn’t easily interchangeable between different regions. This created significant hurdles for trade and the expansion of electrical systems. As the industry matured, the need for common standards became obvious, driving the eventual adoption of the two dominant frequencies we see today.

Industrial and Specialized Applications

While 60 Hz is the standard for most of the world’s power grids, some specific industrial and specialized uses benefit from different frequencies. It’s not just about lighting up homes; industry has its own set of needs.

High-Frequency Use in Aviation

Ever wonder why aircraft equipment often uses a higher frequency, like 400 Hz? It all comes down to size and weight. For planes and ships, every pound and cubic inch counts. At 400 Hz, transformers and motors can be made significantly smaller and lighter compared to their 60 Hz counterparts, while still delivering the same power. This makes a big difference in an environment where space and weight are at a premium. The U.S. military even has a standard, MIL-STD-704, specifically for 400 Hz power in aircraft.

Industrial Plant Power Requirements

In large industrial settings, the choice of frequency can impact the performance of machinery. For instance, induction motors run at a speed directly related to the frequency. A higher frequency allows motors to achieve higher speeds for a given size, meaning you can get more power out of a smaller motor. This is a big deal when you’re trying to pack a lot of machinery into a factory floor. However, transmitting power at these higher frequencies over long distances becomes problematic due to increased impedance, so these systems are usually confined to a specific building or complex.

The Role of Frequency in Generator Performance

Generators are designed to operate at specific frequencies. When you’re looking at industrial backup power solutions, the generator’s output frequency is a key consideration. For example, some older equipment or specific processes might be sensitive to frequency variations. Maintaining a stable frequency is vital for the reliable operation of connected machinery. This is where understanding the nuances of generator performance and matching it to the load becomes important. For many businesses, reliable commercial diesel generator uses are a must-have to keep operations running smoothly, regardless of grid stability. You can find a wide variety of generator options available to suit different industrial needs at places that specialize in generator sales.

The efficiency and size of electrical components like transformers and motors are directly influenced by the frequency of the power supplied. Higher frequencies allow for smaller, lighter equipment, which is a significant advantage in mobile or space-constrained applications. However, the electrical characteristics of transmission lines make very high frequencies impractical for long-distance power distribution.

Legacy Systems and Frequency Conversion

Remnants of Lower Frequency Grids

Even though 60 Hz is the standard in many places now, you can still find older electrical systems chugging along at different frequencies. Back in the day, frequencies like 25 Hz were actually pretty common, especially for things like railway electrification and powering large industrial motors. It made sense at the time because certain equipment, like rotary converters used to change AC to DC, worked better at these lower speeds.

Some of these older systems hung around for a long time, with places like Niagara Falls keeping 25 Hz generators running into the 2000s just so big industrial customers didn’t have to upgrade their old machinery. It’s kind of like how some people still use old vinyl records even though digital music is everywhere.

Challenges of Frequency Conversion

Switching from an old frequency to a new one isn’t a simple flip of a switch. It’s a massive undertaking. Think about it: every motor, every transformer, every piece of equipment connected to the grid might need to be replaced or significantly modified. This is incredibly expensive and disruptive.

For instance, trying to connect a 25 Hz system to a 60 Hz system using machines that convert the frequency is tricky. A 60 Hz machine with 24 poles spins at the same speed as a 25 Hz machine with 10 poles. That means the conversion machines themselves have to be big, slow, and costly to build. Plus, every time you convert power, some energy is lost in the process, which adds to the inefficiency.

Rotary Converters for Interoperability

So, how did they bridge the gap between these old and new systems? Rotary converters were a big deal. Before modern solid-state electronics, these machines were the go-to for changing AC power from one frequency to another, or even from AC to DC. They’re basically big motor-generator sets. They worked better with lower frequencies, which is why they were often used to supply 60 Hz power from a 25 Hz generation source. While they allowed different systems to connect and exchange power, they weren’t perfect. They were bulky, required regular maintenance, and, as mentioned, wasted some energy during the conversion.

You can still find these kinds of frequency changers today, connecting older parts of the grid to the main system, but they’re a constant reminder of the electrical past and the ongoing effort to keep everything running smoothly. It’s a bit like having a special adapter to make your old phone charger work with a new phone; it gets the job done, but it’s not the ideal solution. For those looking into independent power, understanding how different systems interact is key, much like understanding the components of off-grid power solutions.

| Original Frequency | Target Frequency | Conversion Method | Notes |

|---|---|---|---|

| 25 Hz | 60 Hz | Rotary Converter | Common for industrial loads and railway systems |

| 16.7 Hz | 50 Hz | Motor-Generator Set | Used in some European rail networks |

| 60 Hz | 400 Hz | Static Frequency Converter | Used for specialized applications like aircraft |

Factors Influencing Frequency Standardization

So, why do we have different power frequencies around the world, like the 60 Hz common in North America and the 50 Hz used in Europe? It wasn’t just a random pick; a bunch of things played a role in settling on these standards.

Economic Considerations in Grid Development

When electricity first started powering cities, there wasn’t a single, agreed-upon frequency. Lots of different frequencies were in use, and it was a bit of a free-for-all. Companies were just trying to get power out there, and whatever worked best for their immediate needs became the standard for their area. The cost of building new infrastructure was a huge factor. If a company had already invested heavily in equipment designed for, say, 25 Hz, they were less likely to switch to 60 Hz unless there was a really compelling reason.

Think about it like this: if you’ve bought a whole fleet of trucks that run on diesel, switching to electric overnight would be incredibly expensive and disruptive. The same applied to early power grids. The initial investment in generators, transformers, and motors really locked in certain frequencies for different regions. This is why you see remnants of older frequencies still popping up even today.

The Influence of Major Manufacturers

Big companies had a massive impact on which frequencies became dominant. In the United States, Westinghouse, with its backing of Nikola Tesla’s AC system, really pushed for 60 Hz. They saw it as a good balance for their growing power needs, especially for things like lighting and motors. It allowed for slightly smaller and lighter transformers, which was a cost saver for the vast U.S. grid. Across the Atlantic, European companies, particularly in Germany, were leaning towards 50 Hz.

This frequency worked well with the technology and machinery they were developing at the time. Because these companies were exporting their equipment, their chosen frequencies tended to spread to other countries, especially those that were colonies or had strong trade ties. So, a company’s decision could end up influencing an entire continent’s electrical system. It’s fascinating how these early business choices still affect us today, like when you’re looking to buy a generator and need to make sure it’s compatible with your local power grid frequency.

The Cost of Rewiring National Grids

Once a frequency standard is established and a country’s electrical infrastructure is built around it, changing it becomes a monumental task. Imagine trying to replace every single light bulb, appliance, motor, and piece of industrial equipment in an entire nation, not to mention upgrading the power lines and substations themselves. It’s a mind-bogglingly expensive and complex undertaking.

This is why, even when a different frequency might offer some theoretical advantages, the sheer cost and disruption of a nationwide switch usually prevent it. Most countries have stuck with the frequencies that became dominant decades ago. The practical reality is that it’s far more economical to manage the existing system and, if necessary, use converters for any equipment that might operate on a different frequency. It’s a classic case of sunk costs dictating future decisions.

Understanding Power Frequency Variations

So, the power coming into your house isn’t always exactly 60 Hz, or 50 Hz for that matter. It’s a bit like a busy highway; sometimes things slow down, sometimes they speed up a little.

Grid Load and Frequency Fluctuations

Think of the electrical grid as a giant, interconnected system. When lots of people are using a lot of electricity at once – say, during a heatwave when everyone’s running their air conditioners – the generators have to work harder. This extra demand can actually cause the frequency to dip slightly. On the flip side, when demand is low, like in the middle of the night, the frequency might creep up a bit. These small, temporary shifts are normal. They’re a sign that the system is responding to real-time demand.

The Function of Time Error Correction

Because the frequency can fluctuate, some older electric clocks actually used these tiny variations to keep time. If the frequency was a little low, the clock would run slow; if it was a bit high, it would run fast. To fix this, grid operators use something called Time Error Correction (TEC). Basically, they make tiny adjustments to the overall generation to make sure that over a longer period, the total number of cycles matches what it should be. This keeps things like those old clocks (and other time-sensitive equipment) accurate.

The Role of a Diesel Generator in Power Stability

When you have a diesel generator, especially in a critical facility like a hospital or a data center, it’s not just about having backup power. These generators can also help stabilize the local electrical supply. If the main grid frequency drops, a generator can sometimes be used to help bring it back up, or at least maintain a more stable frequency for the equipment it’s powering. It’s like having a small, dedicated power source that can smooth out the bumps from the larger grid.

Here’s a quick look at how generator speed relates to frequency:

| Generator Poles | Rotational Speed (RPM) at 60 Hz |

|---|---|

| 2 | 3600 |

| 4 | 1800 |

| 6 | 1200 |

| 8 | 900 |

| 10 | 720 |

| 12 | 600 |

It’s pretty interesting how all these pieces fit together. The grid is constantly balancing act, and frequency is one of the key indicators of that balance. Even small changes tell a story about what’s happening with electricity demand and supply.

The Legacy of 50 Hz vs. 60 Hz

So, as we’ve seen, the reason some places use 60 Hz power while others stick with 50 Hz is really a historical thing. It goes back to the early days of electricity when different companies and countries made different choices based on what worked best for their equipment and plans at the time. It’s kind of wild to think that these old decisions still affect how we get power today.

While most of the world settled on either 50 or 60 Hz, you can still find some older or specialized systems running on different frequencies, though they’re not common for everyday use. For most of us, 60 Hz is what powers our homes and businesses in places like North America and parts of Asia, powering everything from our lights to our computers, and it’s just a standard we’ve all gotten used to.

Frequently Asked Questions

Why do some countries use 60 Hz power while others use 50 Hz?

The difference between 50 Hz and 60 Hz power systems mostly comes down to history. Early on, different companies and countries made choices based on what worked best for their technology at the time. For example, Westinghouse in the U.S. chose 60 Hz partly because it worked well for both lights and motors, and maybe because it was easier for some calculations. In Europe, companies like AEG favored 50 Hz, which was also a good balance for early electrical equipment. These choices stuck and spread as their electrical systems grew.

Where is 60 Hz power most commonly used?

North and Central America are the main regions that use 60 Hz power. This includes the United States, Canada, and Mexico. Some countries in South America, like Brazil, also use 60 Hz. Parts of Asia, such as Japan’s western region, also operate on 60 Hz.

Are there any special places that use frequencies other than 50 Hz or 60 Hz?

Yes, some special applications use much higher frequencies, like 400 Hz. You’ll find this on airplanes, in spacecraft, and for certain military equipment. This high frequency allows for smaller and lighter electrical parts, like transformers and motors, which is a big advantage when space and weight are limited. However, these high frequencies can’t be sent over long distances easily.

What is ‘utility frequency’?

Utility frequency, also called line frequency or mains frequency, is simply the normal speed at which electricity alternates back and forth in the power lines that supply homes and businesses. Most of the world uses either 50 Hz or 60 Hz for this.

Can a generator be changed from 50 Hz to 60 Hz?

Sometimes, yes. An experienced technician can often adjust a generator to run at a different frequency. However, changing the frequency usually means changing the engine’s speed. Slowing it down for 50 Hz might reduce its power output, while speeding it up for 60 Hz might increase it. There can be a drop in performance when converting from 60 Hz to 50 Hz because the engine has to run slower.

Why don’t all countries just use the same power frequency?

Switching national power grids to a different frequency is incredibly difficult and expensive. It would involve changing almost all the electrical equipment in the entire country, from power plants to factories to people’s homes. Because it costs so much and would cause so much disruption, countries tend to stick with the frequency they originally adopted, even if another frequency might seem more convenient now.

One Comment